What is a Transformerless Power Supply?

A transformerless power supply is a type of power supply that converts high AC input voltage (typically 120V or 230V) directly to a low DC output voltage (such as 3V, 5V, or 12V) without the use of a traditional step-down transformer. These power supplies are particularly advantageous in low-power, space-constrained, or cost-sensitive applications.

Key Characteristics:

- Low Cost: Without the transformer, the cost of the power supply is significantly reduced.

- Compact Size: The elimination of bulky transformers allows for a more compact design.

- Simple Construction: The circuit design is straightforward, making it easier to implement in various applications.

However, these advantages come with some trade-offs, including the lack of isolation between the high-voltage AC input and the low-voltage DC output, which can pose safety risks.

Working Principle of a Transformerless Power Supply

The fundamental principle of a transformerless power supply is based on a voltage divider circuit that converts high AC voltage to a lower DC voltage without using a transformer. The circuit typically involves the following key stages:

- Capacitive Dropping: A capacitor connected in series with the AC input reduces the voltage by limiting the current. This process is based on the capacitive reactance, which is inversely proportional to the frequency and capacitance.

- Rectification: The reduced AC voltage is then rectified using a bridge rectifier, which converts the AC voltage to pulsating DC voltage.

- Filtering: A capacitor filters out the ripples from the pulsating DC voltage to produce a smoother DC output.

- Regulation: A Zener diode regulates the output voltage to a specific level (e.g., 12V), ensuring a stable and consistent voltage supply.

- Current Limiting and Protection: Resistors are used to limit the current and protect the circuit from inrush current, which could otherwise damage the components.

Designing a 12V Transformerless Power Supply

Components Required

To design a 12V transformerless power supply, the following components are essential:

- X-Rated Capacitor (C1): 225k/400V

- Discharge Resistor (R1): 470kΩ, 1W

- Bridge Rectifier: Diodes (D1, D2, D3, D4)

- Filter Capacitor (C2): 470μF, 100V

- Zener Diode: For 12V regulation

- Current Limiting Resistor (R2): 220Ω, 1W

- Indicator LED: To signal the presence of output voltage

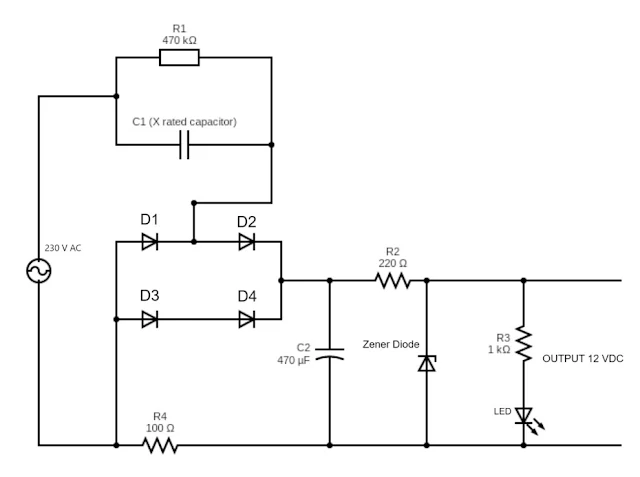

Circuit Diagram Description

- Capacitive Dropping Stage:The circuit begins with an X-rated capacitor (C1) connected in series with the AC mains. This capacitor acts as a current-limiting device, reducing the high AC voltage to a safer level. The reactance of the capacitor is crucial in determining the amount of current flowing through the circuit. A discharge resistor (R1) is connected across the capacitor to safely discharge it when the circuit is turned off, preventing electrical shock.

- Rectification Stage: After the voltage has been reduced by the capacitor, it passes through a bridge rectifier made up of four diodes (D1, D2, D3, D4) [IN4007]. The bridge rectifier converts the reduced AC voltage to pulsating DC voltage.

- Filtering Stage: The pulsating DC output from the rectifier is then passed through a filter capacitor (C2). This capacitor smooths out the ripples, resulting in a more stable DC voltage.

- Voltage Regulation Stage:The smoothed DC voltage is further stabilized by a Zener diode, which is designed to regulate the voltage to 12V. The Zener diode ensures that the output remains at 12V even if the input voltage varies slightly.

- Current Limiting and Indication: A current-limiting resistor (R2) is included in series with the Zener diode to protect it from excessive current. Additionally, an LED can be connected to the output as an indicator to show that the circuit is functioning correctly.

Safety Considerations in Transformerless Power Supply Design

While transformerless power supplies offer several benefits, they also come with certain risks, particularly due to the lack of galvanic isolation between the input and output. This lack of isolation means that any fault or failure in the circuit could expose the user to dangerous high voltage. To mitigate these risks, consider the following safety measures:

- Enclosure: The entire circuit should be enclosed in a well-insulated, shockproof case to prevent accidental contact with live components.

- Isolation Transformer: For added safety, an isolation transformer can be added at the input stage to provide isolation from the mains supply. This addition, however, somewhat negates the space and cost advantages of the transformerless design.

- Proper Grounding: Ensure that the circuit is properly grounded to avoid potential electric shock hazards.

- Component Ratings: All components, particularly the capacitor and diodes, should be rated for higher voltages than the maximum input to account for voltage spikes and surges.

Types of Transformerless Power Supplies

Transformerless power supplies can be categorized into two main types based on the method of voltage reduction:

- Resistive Transformerless Power Supply: In this type, a resistor is used to drop the voltage. While simple, this method is inefficient because the resistor dissipates excess energy as heat, leading to significant power loss.

- Capacitive Transformerless Power Supply: A capacitive transformerless power supply, like the one described in this article, uses a capacitor to drop the voltage. This method is more efficient, as the capacitor does not dissipate energy as heat. Capacitive power supplies are commonly used in low-power applications where efficiency is crucial.

Applications of Transformerless Power Supplies

Transformerless power supplies are ideal for low-power, low-cost applications. Some common applications include:

- LED Bulbs: Due to their compact size and low cost, transformerless power supplies are widely used in LED lighting applications.

- Mobile Chargers: Transformerless designs are often employed in compact mobile chargers where space and cost are critical factors.

- Electronic Toys: Many battery-operated or low-power toys use transformerless power supplies to keep costs low.

- Emergency Lights: Transformerless power supplies are used in emergency lighting systems, providing reliable power to LEDs or other light sources.

- Telecommunication Equipment: Low-power telecommunication devices can benefit from transformerless power supplies due to their compact size and efficiency.

- Small Household Appliances: Transformerless power supplies are used in various small appliances, such as timers, clocks, and sensor-based devices.

Advantages and Disadvantages

Advantages:

- Cost-Effective: Without the need for a transformer, the overall cost of the power supply is reduced.

- Compact Size: The absence of a bulky transformer allows for a more compact design.

- Simplicity: The circuit is straightforward and easy to implement in low-power applications.

Disadvantages:

- Lack of Isolation: The absence of galvanic isolation between the input and output can pose safety risks.

- Limited Current Output: Transformerless power supplies are typically limited to low current outputs, making them unsuitable for high-power applications.

- Potential Safety Risks: Due to the lack of isolation, the circuit must be carefully enclosed and insulated to prevent accidental contact with high-voltage components.

Conclusion

Transformerless power supplies offer a practical and cost-effective solution for powering low-power electronic devices. By understanding the working principles, design considerations, and safety precautions, you can effectively implement a transformerless power supply in various applications. While they have limitations, particularly in terms of safety and current capacity, their advantages in cost, size, and simplicity make them an attractive option for many low-power electronics projects.